Component integration is a key strategy in the EV industry. Increasingly, multiple powertrain components, such as the motor, inverter, on-board charger and DC-DC converter, are combined into a single compact unit. This approach delivers significant benefits in efficiency, weight reduction and space optimization. However, it also presents new engineering challenges, particularly in managing heat dissipation and ensuring long-term reliability at higher power densities.

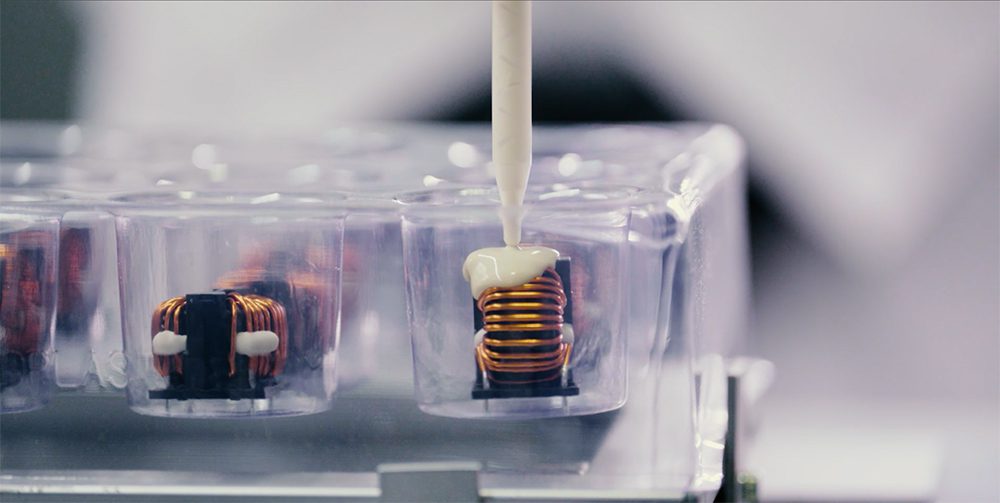

Henkel aims to help OEMs and suppliers overcome these challenges with its portfolio of high-performance thermal potting materials, which the company has now expanded with the dual launch of Loctite SI 5643 and Loctite SI 5637. These two new thermal potting solutions are optimized for EV power conversion components such as on-board chargers and inverters. They offer different levels of thermal conductivity to address a wide range of design needs.

“Both Loctite SI 5643 and Loctite SI 5637 are two-component, fast-curing, low-viscosity thermally conductive silicone potting compounds for high-performance power electronics,” Henkel explains. “Thanks to their exceptional fast-flowing characteristics, they provide pourable, self-levelling potting solutions capable of filling small gaps, providing outstanding physical protection to sensitive components while delivering exceptional heat transfer for thermal management.”

Both products feature very low Shore hardness and flexibility, which enables them to protect electrical and electronic components against vibration without adding mechanical stress during thermal cycling.

“The launch of Loctite SI 5643 and Loctite SI 5637 further strengthens our pioneering role in creating e-mobility solutions developed in close partnership with OEMs, battery manufacturers and automotive suppliers to meet emerging challenges in areas such as thermal management,” said Matthias Brachmann, Business Development Manager E-Mobility Power Conversion and E-Drive Systems at Henkel.

“Thanks to the collaborative relationships with our automotive customers, Henkel is addressing the industry’s biggest challenges through the development of advanced materials [for] next-generation power electronics and EV battery designs,” said Tobias Knecht, Global Head of Market Strategy, E-Mobility at Henkel. “The pace at which innovative products like Loctite SI 5643 and Loctite SI 5637 can progress from laboratory to assembly lines is a testament to our commitment to this vital sector.”

Source: Henkel