NewGenium, a technology company based in Pasadena, California, has announced its SuperSynth process, a direct brine-to-lithium-iron-phosphate (LFP) manufacturing technology. According to NewGenium, SuperSynth reduces the cost and complexity of LFP production by enabling extraction of lithium directly from brine, consolidating extraction and synthesis steps and eliminating the need for offshore processing. The company reports that its proprietary process offers a scalable route to domestic LFP cathode manufacturing for lithium-ion batteries.

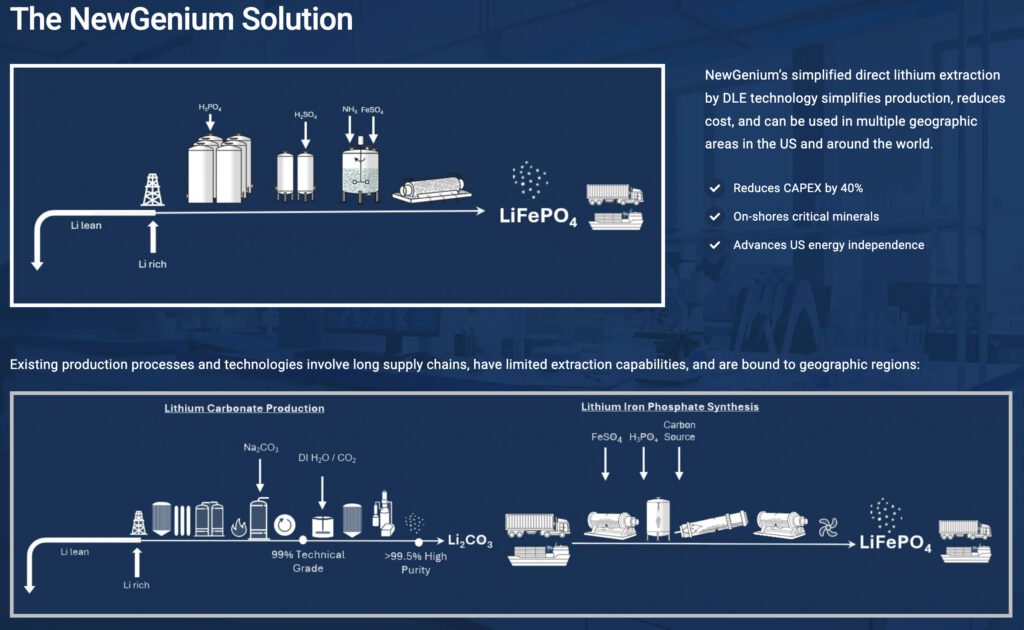

The technology streamlines LFP production to three low-temperature unit operations using common process equipment. NewGenium claims the approach yields significantly less solid waste and achieves a levelized cost of roughly $3 per kilogram of LFP—substantially lower than the current $5 to $15 per kilogram market rate, which includes duties and tariffs. NewGenium’s ion exchange direct lithium extraction (DLE) and in-lab LFP production were proven at its Monrovia, California facility in 2025.

Target applications for SuperSynth include US-based upstream well operators and downstream cathode and battery manufacturers, particularly those producing battery packs for electric vehicles and battery energy storage systems. NewGenium says its process addresses a key challenge in US battery supply chains: converting domestic lithium-rich brines into battery-grade LFP cathode material without relying on international processing or imports. The company references a 2024 US Geological Survey study estimating up to 19 million tons of lithium in US brine reserves, enough to support current demand for nearly 100 years.

Traditional methods typically generate lithium carbonate through evaporation ponds, which require substantial land and multi-year processing periods followed by international transport for LFP synthesis. NewGenium’s process is positioned as an alternative that consolidates and simplifies this supply chain.

“The USA faces a critical moment in which the exploding demand for lithium batteries is not matched by our capacity to produce the necessary LFP cathode materials,” said Christopher Murphy, CEO at NewGenium. “Given the new mandates for energy and critical mineral independence, the country’s battery industry must take advantage of domestic reserves and produced water using DLE technologies. We’re thrilled to have developed a novel chemical process that will help the USA build national independence in critical minerals by extracting lithium from brine and turning it into LFP in a simplified way. Perhaps most exciting is the fact that onshoring USA domestic production of LFP batteries from brine finally becomes both financially and environmentally attractive.”

Source: NewGenium