Danfoss Power Solutions is supplying its Editron eDrive to VTS Track Solutions to propel the company’s new Fero Tracked Carriers. The ETP-10 and ETP-20 are remote-controlled battery-electric carriers designed for material transport in construction, forestry, landscaping, workshops and other applications.

Material carriers are used to easily and safely transport heavy items heavy materials around job sites. Electric carriers are preferred, as they produce no exhaust fumes and little noise. They also comply with regulations requiring use of emission-free machinery on urban building sites, and may qualify for subsidies in some jurisdictions.

Drawing on its expertise in producing undercarriages and power packs for tracked machinery, VTS Track Solutions developed Fero Carriers, a new generation of rugged, compact battery-electric tracked vehicles capable of operating in multiple terrains and conditions.

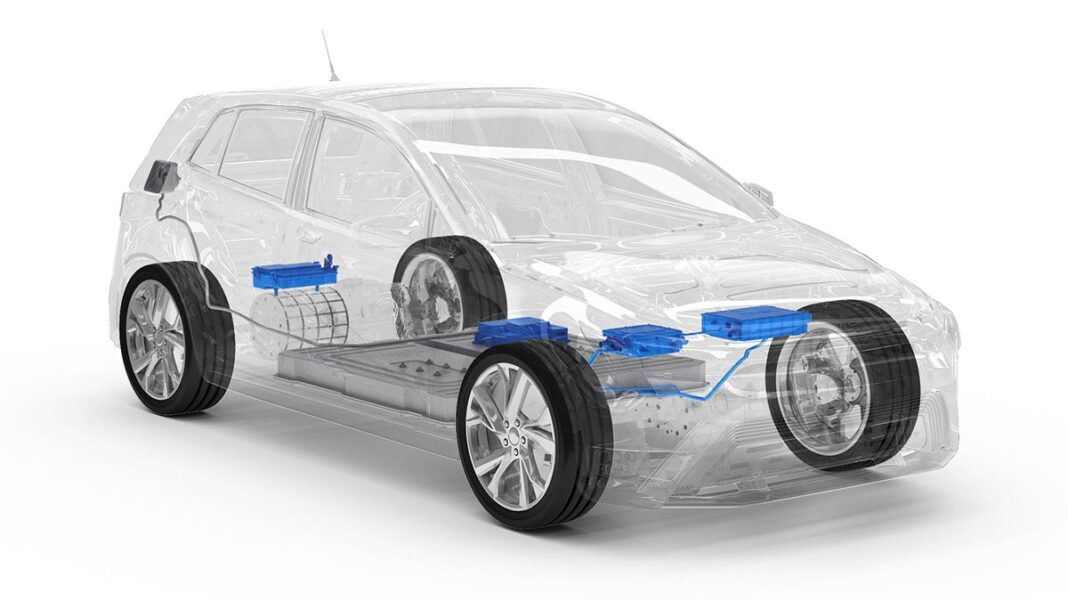

To power its Fero Carriers, VTS selected the Danfoss Editron eDrive, a propulsion system for compact, low-voltage machinery that comprises an inverter and two interior permanent magnet electric motors integrated with gearboxes.

“We chose Danfoss because of its brand quality, robust engineering standards, and the availability of a complete, well-matched propulsion package,” explained VTS engineer Daan van Kerkhoff. “The dual-controller configuration was especially valuable for our design, as it minimizes the number of separate components and saves critical installation space within the center frame.”

Danfoss personnel worked with VTS engineers to customize the eDrive system software for the tracked machine, which requires independent speed control for the two motors. Danfoss engineers also assisted with system layout, parameter tuning, validation testing and integration guidance. “This collaboration not only accelerated our design process but also strengthened our confidence in delivering a technically solid and future-proof product,” van Kerkhoff added.

The ETP-10 has a 1,000-kilogram load capacity and platform dimensions of 1,236 by 780 millimeters. It has two travel speeds, with a maximum of 4 kilometers per hour. Its 24-volt lithium-ion battery has a capacity of 2.5 kWh and can charge in 3.5 hours. Optional accessories such as stanchions, an electric winch, tow hitc, and tilting container enhance the machine’s versatility.

The ETP-20 has a load capacity of 2,000 kg, and a larger rotating platform measuring 1,445 by 780 mm. It has a 48 V battery and 3 kph maximum speed.

Source: Danfoss Power Solutions