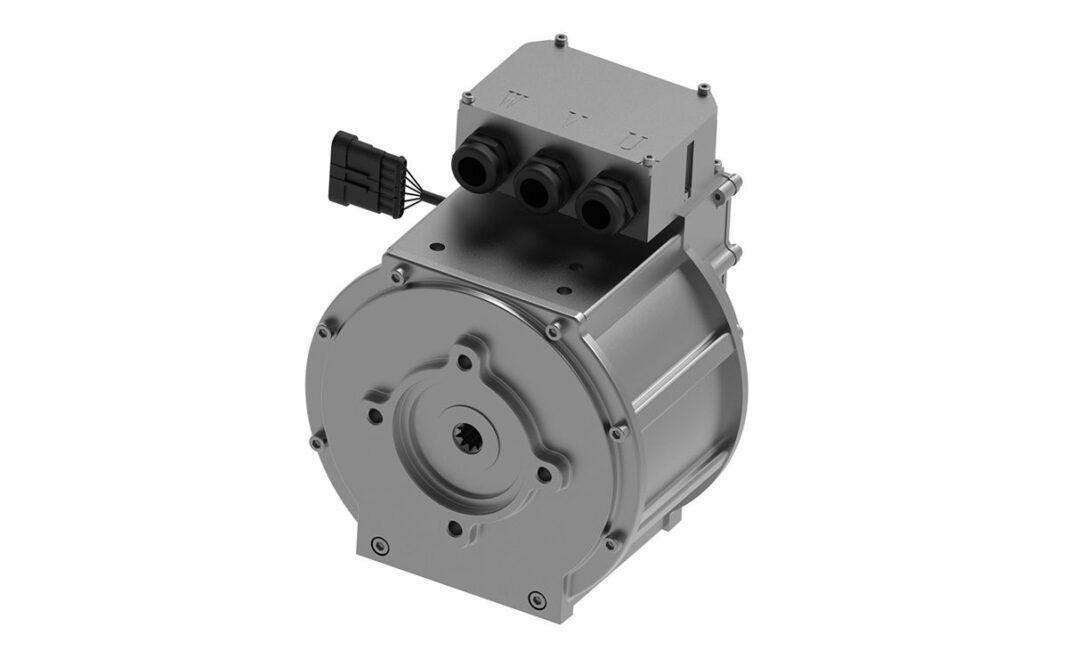

Danfoss Power Solutions has announced the Editron EM-PMI180, a new 48-volt synchronous reluctance-assisted permanent magnet motor engineered to power hydraulic gear pumps in compact electric machinery, such as boom lifts, scissor lifts, compact loaders, and excavators.

The PMI180 is designed to replace larger, less efficient AC induction motors, which are commonly used to drive hydraulic work functions in mobile elevating work platforms. Danfoss says the 180 mm diameter SRPM motor offers 15 percent greater efficiency and 15 percent smaller volume compared to AC induction motors delivering equivalent power and torque. It features hairpin windings, which further increase power density and efficiency beyond what is achievable with conventional round wire windings.

Editron PMI180 specs include a 7 kW rated power at 48 volts DC, 3,000 rpm rated speed (with a maximum speed of 4,000 rpm), 22.5 Nm rated torque (with up to 90 Nm maximum torque) and a standard gear pump interface supporting pumps up to 16 cubic centimeters at 240 bar. The motor is protected by an IP67 ingress rating against dust and moisture, and Danfoss says its corrosion resistance has been validated via a 200-hour salt-spray test.

The PMI180 is intended to work with Danfoss’s EC-C48 inverter, planned for availability in 2026, and supports integration in machines where battery packs and other components compete for limited space.

The company also announced the upcoming ED-DT180 eDrive, a 48-volt electric drive that combines a motor, reduction gearbox and electromagnetic brake for MEWPs and similar off-highway vehicles, joining the 24-volt system launched in 2024.

“Editron has long been known for its high-voltage electrification solutions. Now we are strategically building out our low-voltage product lines to encompass 24- and 48-volt solutions,” said Eric Wang, Application Engineering and Portfolio Manager, Editron China, Danfoss Power Solutions. “PMI180 is built on advanced technology, a proven product development process, and decades of mature, global manufacturing and quality control, which means the motor is not only state-of-the-art, but also highly reliable and built to last.”

Source: Danfoss