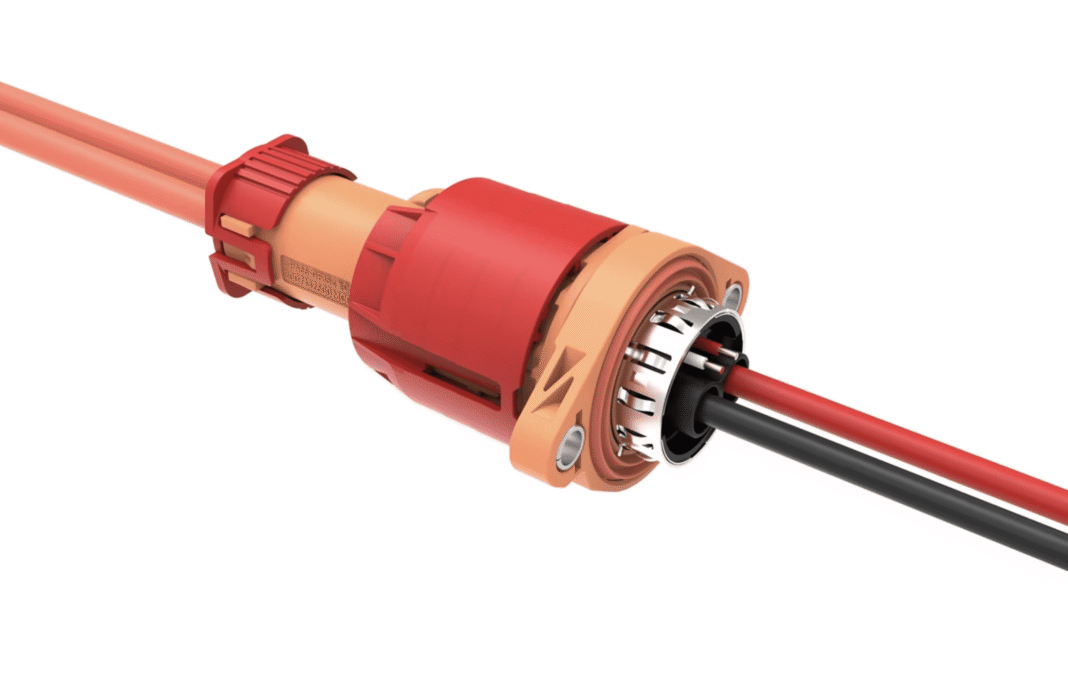

Molex has announced the launch of its eHV60 high-voltage automotive connector, the first product in its new eHV high-voltage connector and terminal system portfolio. Molex says the eHV60 is purpose-built for auxiliary high-voltage functions, including DC/DC converters, onboard chargers, electric compressors and e-axles in battery electric vehicles and plug-in hybrid electric vehicles.

The connector is designed to combine a compact form factor with robust electrical and mechanical reliability, addressing growing space constraints in modern electric vehicle architectures. The eHV60 supports up to 1000 V and 64 A at 80°C, making it suited for mid-power auxiliary applications. The connector’s shielded interface provides enhanced protection against electromagnetic interference (EMI), which is essential for maintaining signal integrity and overall system safety in high-voltage EV systems.

Molex says that the eHV60 occupies up to 30 percent less space compared to existing alternatives, enabling easier integration into compact system designs. The eHV60 has been validated both electrically and mechanically as a drop-in replacement, offering automotive original equipment manufacturers (OEMs) and Tier 1 suppliers the option to source from multiple validated suppliers without revising existing system layouts.

Molex highlights adherence to USCAR-2 and LV215 industry standards and notes global compliance and qualification readiness.

“The new eHV60 aligns with Molex’s broader automotive portfolio to strengthen supply chain resiliency and reduce total manufacturing costs,” said Scott Whicker, Senior Vice President and President of Transportation and Innovative Solutions at Molex. “This newest extension to our eHV high-voltage connector portfolio offers a compact, efficient solution that increases sourcing flexibility while easing integration into space-constrained systems.”

Molex expects to make the eHV60 available in the first quarter of 2026.

Source: Molex